Cost Saving Benefits of the V.I.P. Inspection Plug

- Helps to prevent Corrosion under Insulation (C.U.I.)

- The V.I.P. makes non-destructive inspection economical

- Reduces inspection costs and time

- Provides ready access for inspection with minimum exposure to vessel insulation

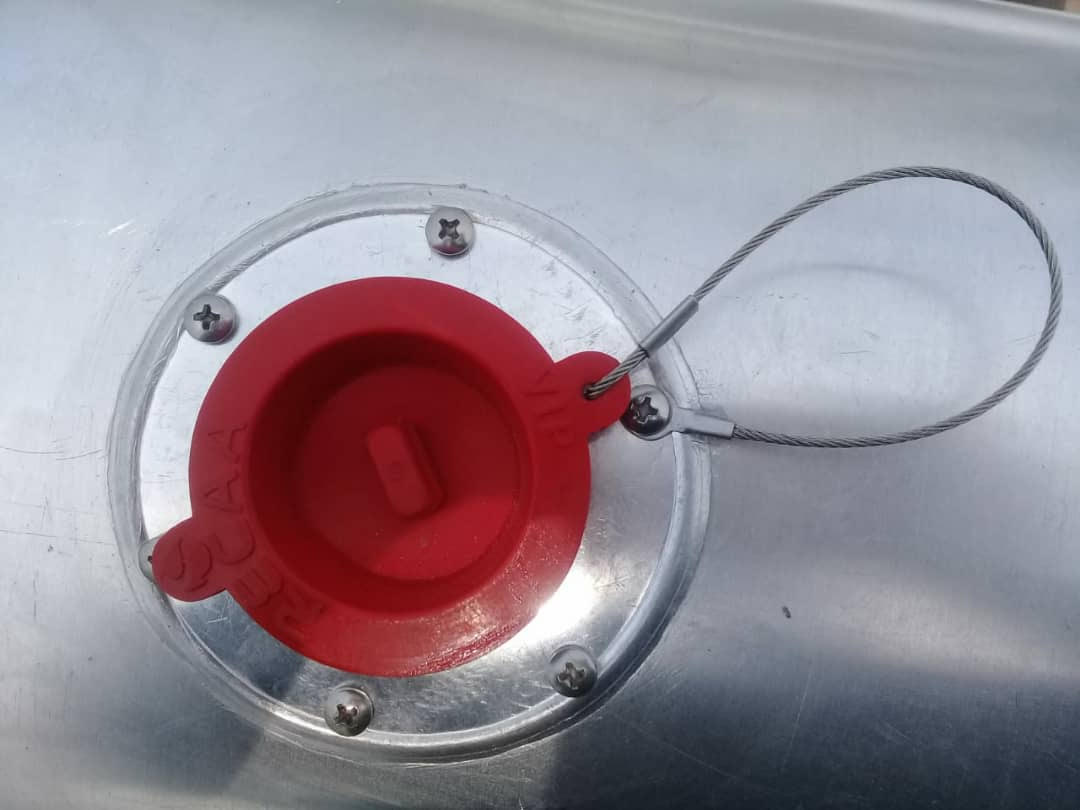

- High visibility and provides a consistent inspection point ensuring future inspections are taken at same location

- Maintains a weather-tight seal to protect insulation

- Reduces inspection costs/ time

- High temperature silicone plug provides long service life

- Inspection points can be bar coded for data log entry.

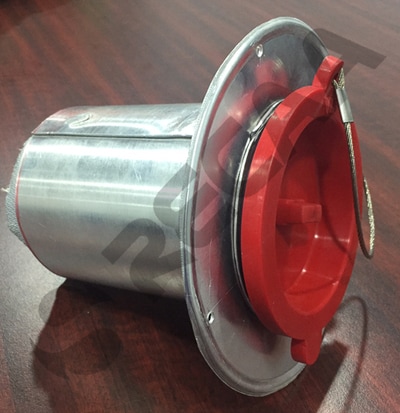

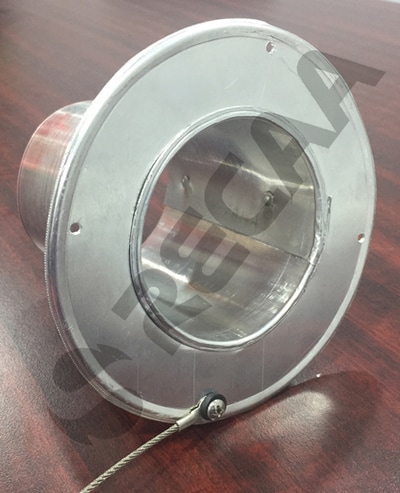

Installing the Inspection Window with the V.I.P.

- Cut hole through insulation jacket with hole-saw to correspond with plug-size to be installed.

- Remove insulation and clean external surface.

- Insert the Jacketing Sleeve into the hole and secure with self tapping screw and apply Silicon sealant around the external of sleeve.

- Insert the Insulation infill in correspondence of the original insulation thickness and materials insert Inspection Plug into hole to cover insulation.

- Make sure plug is fully seated by depressing centre of plug firmly with thumb or fingers.

- Plug is now correctly installed and ready for periodic vessel inspection operation.

Specifications

- Sizes 2”, 3″ and 5”

- Plug material Std. MTL 40

- Durometer silicone rubber

- Temp. range -60ºC. tot 260ºC

- Std. Colour : Red

- Eyelet Material: SS304